-

How To Install The Check Valve

1.Swing check valve: Swing check valve disc is disc-shaped, around the seat of the axis of rotation for rotary axis movement, because the valve channel into a streamlined, flow resistance than the lift check valve is small, It is suitable for large caliber applications where the flow rate is low and the flow is not constant, but it is not suitable for pulsating flow and its sealing performance is not as good as that of lifting. Swing check valve is divided into single-valve type, double-valve type and more than three types, these three forms are mainly divided by the valve caliber, the purpose is to prevent the media stop flow or reverse flow, weakening the hydraulic shock.

2.The lift check valve: valve flap along the vertical centerline of the slide valve, lift check valve can only be installed in the horizontal pipe, high-pressure small-caliber check valve disc can be used on the ball . Lift check valve valve body shape and the same (with the cut-off valve common), so it's fluid resistance coefficient. Its structure and cut-off valve is similar to the valve body and the valve and the valve phase

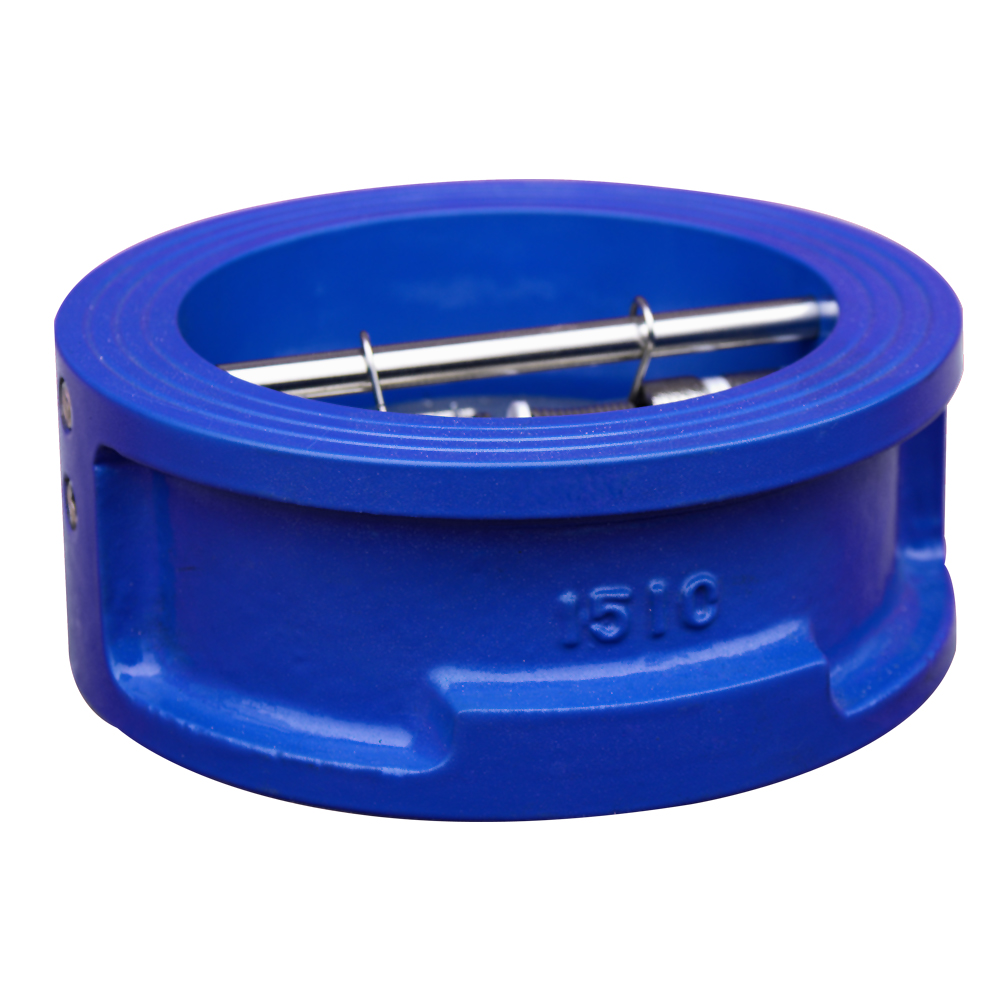

3.The wafer check valve: valve around the valve seat valve pin rotation of the check valve. Disc check valve is simple, can only be installed in the horizontal pipe, sealing poor.

4.The pipeline check valve: valve flap sliding along the centerline of the valve body. Pipeline check valve is an emerging valve, its small size, light weight, processing technology is good, is one of the development direction of the check valve. But the fluid resistance coefficient is slightly larger than swing check valve.

5.The compression-type check valve: This valve is used as boiler feed water and steam cut off valve, it has a lift check valve and stop valve or angle valve integrated function.

.jpg)

.jpg)

.jpg)